ATC Limited was founded in Kingston in 1951 by Mr. E. G. Lord, initially designing and supplying tooling packages to automatic lathe users. The company progressed to become a well respected supplier of precision components and assemblies to IBM, NCR, ICL and Timex.

Over the years ATC has supplied its precision engineering services to many kinds of industries including aerospace and medical.

ATC specialise in machining difficult materials and titanium is the major material used on site. High accuracy medical devices for the orthopaedic, neuroscience, cardiac, prosthetic limb and dental industries form the majority of the output.

The company is one of the largest contract medical device manufacturers in the UK and Ireland along with being an FDA registered supplier into the USA.

ATC not only has extensive experience working with titanium but also implant grade (316LVM) stainless steel, cobalt chrome, plastic, peek, aluminium and instrument grade (17-4PH) stainless steel.

Worked throughout the global Covid pandemic with all staff paid 100% of their wages

Invested in new Star SR38 machine for larger implants and instrument manufacture

Invested in 3 new Star SR20 machines to meet growing requirements

Invested in new multi-axis Traub TNL20 ‐ 11 to meet demand from a major customer for very complex screw products that could not be made elsewhere

Investment in 2 new Tornos Sliding Head (Swiss Turn) machines in response to further growth. Upgraded Quality System.

Refurbishment and increase in capacity of electro-polishing for the orthopaedic industry

Investment in drag finishing to speed throughput and increase consistency of products requiring a super-precision cosmetic finish

Significant investment in Laser measurement capacity for measuring components in process and supplying results to customers

Investment in 5 axis capability.

Investment in new Tornos sliding head (Swiss Turn) capacity to provide the most accurate and quick deep drilling capability for ablation components for the treatment of oncology patients

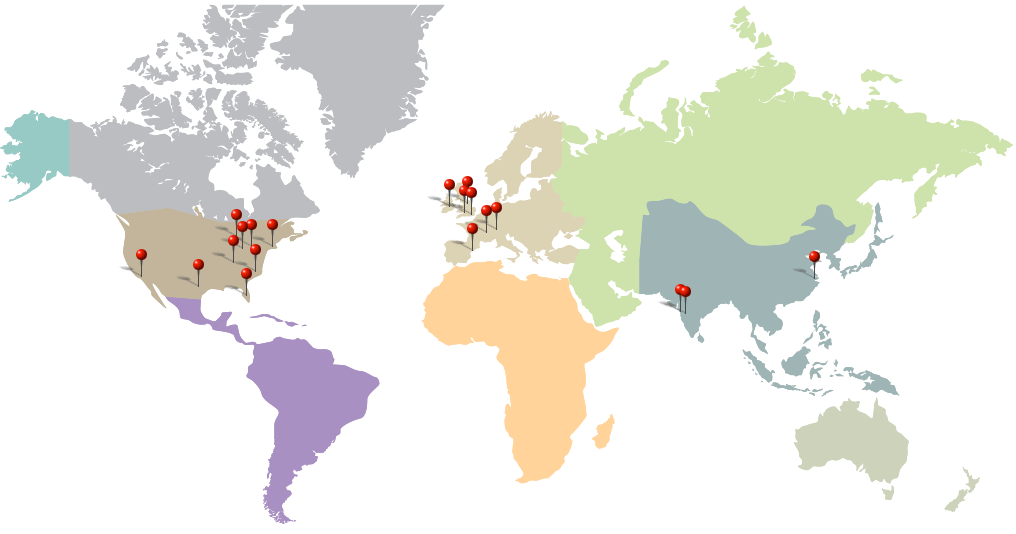

Products now shipped on a monthly basis to the USA, Germany, Switzerland and India. Long term agreement extended with major US customer and others in process.

Perfected the complete manufacture of high accuracy neuroscience implants featuring minimum concentricity tolerance through holes to 1.5mm diameter over 200 mm in length. High accuracy deep drilling of small holes for medical device applications is an ATC specialisation.

Signed first long term agreement with a major US customer for supply of a range of trauma implants.

Moved to state-of-the-art modern manufacturing facility near London Gatwick Airport.

Approved to supply sterile implants on a ship to stock basis. U.S medical customer performance ratings consistently in excess of 95%.

Phase 1 of building project complete. Exports now represent 85% of turnover.

Medical device and orthopaedics account for 85% of turnover. Phase 1 of buildings refurbishment project commenced.

Supplying orthopaedic implants across Europe and the USA.

Registered to EN 46002 & ISO 13488.

Registered to ISO 9001 – internationally registered with FDA quality standards.

Diversified customer base, moving into medical, bearing, electronic, instrumentation and commercial industries.

Invested into first CNC Machine Tools.

Extended manufacturing site by 20,000 sq. ft. Majority of output is defence based.

Approved by MOD to supply defence industry.

Moved to purpose built factory on Holmethorpe Industrial Estate in Redhill.

ATC Limited was founded in Kingston in 1951 by Mr. E. G. Lord, initially designing and supplying tooling packages to Automatics machine users, the company progressed to become a well respected supplier of precision components and assemblies to IBM, NCR, ICL and Timex.